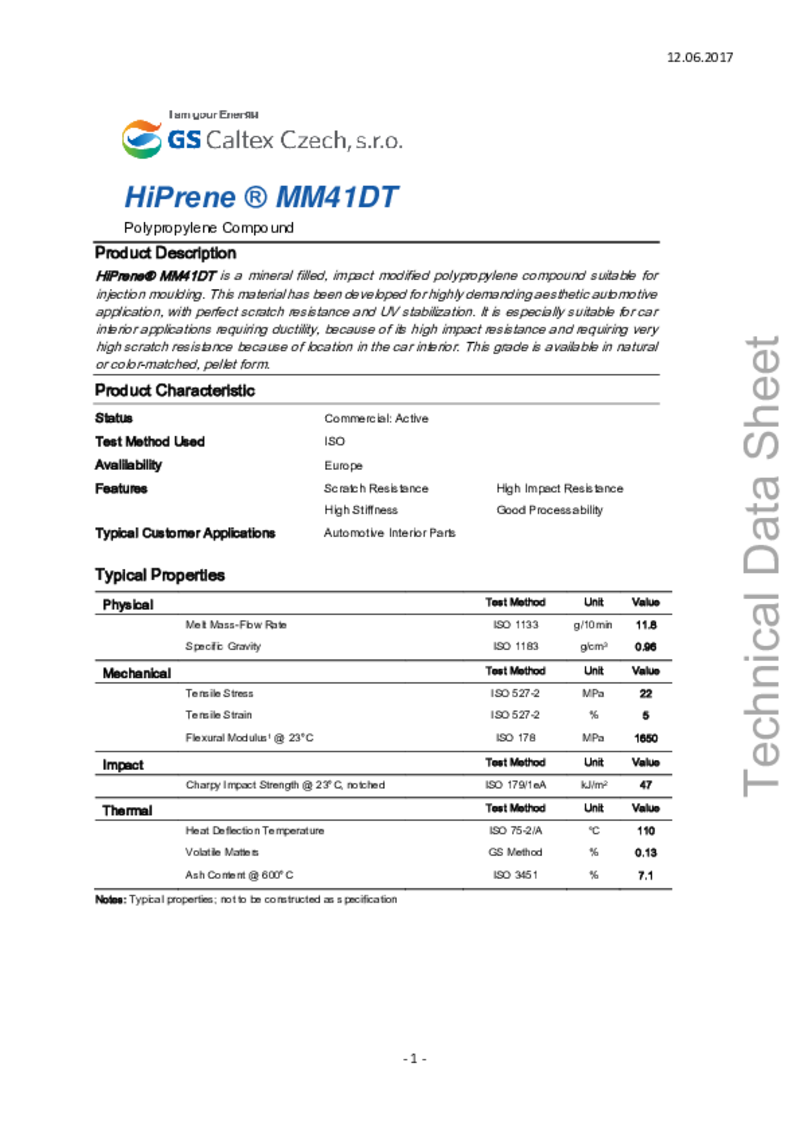

HI-PRENE MM41DT

Produkt anfragen Datenblatt herunterladen Telefonische Beratung +49 40 727702-0

PP+MF

chemisch gekoppelt, Mineralfasergehalt bis 10%, schlagzäh, verzugsarm, UV-Stabil, emissionsarm,

Oberflächengüte, Dichte 0,95

für Automotive Interieur (VW TL 52388-D)

MFR 12g/10min